14

2025

-

04

Step Inside Asia FUJI Elevators’ Smart Factory – Where Precision Engineering Meets Vertical Transportation Excellence

author:

Ada

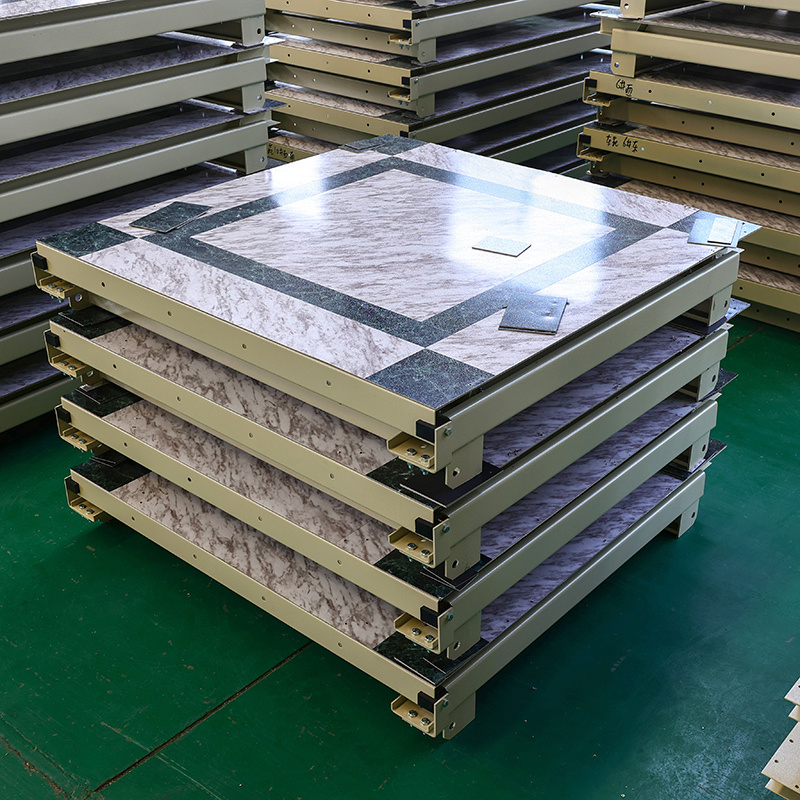

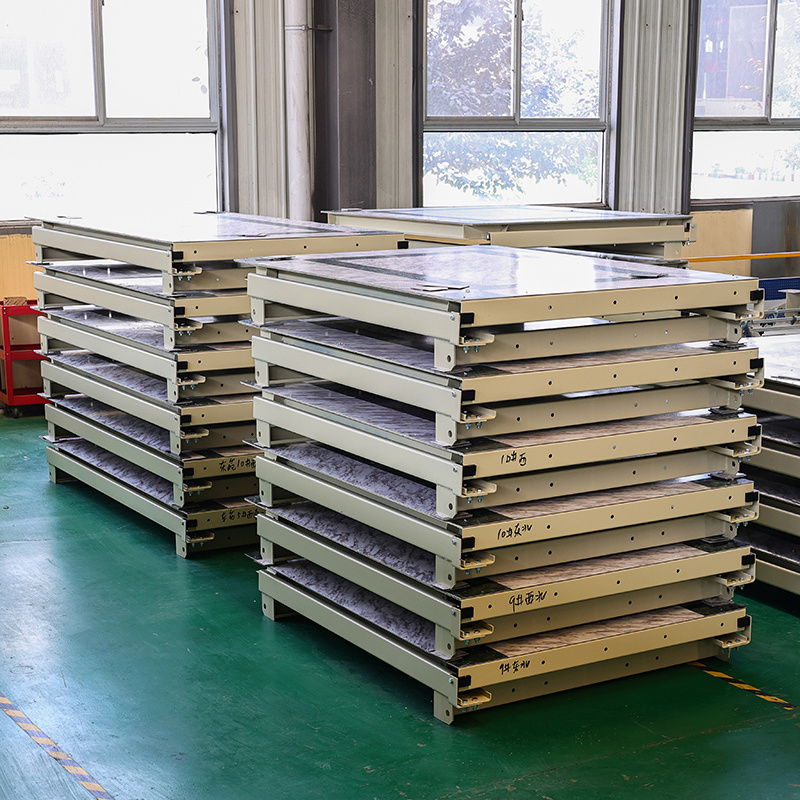

Behind every smooth and safe elevator ride lies an uncompromising pursuit of perfection. Today, we invite you on a visual journey through Asia FUJI Elevators’ production facility, where cutting-edge craftsmanship transforms raw materials into reliable vertical transportation solutions.

-

High-Strength Steel: All load-bearing components use Baowu Group specialty steel with tensile strength exceeding 520MPa.

-

Composite Testing: Elevator car panels undergo 24-hour salt spray tests to ensure 30-year rust resistance.

-

Robotic Welding

-

6-axis robotic arms achieve seamless welds with 0.2mm precision, increasing strength by 35%.

-

-

CNC Machining Centers

-

Guide rail machining tolerances controlled within ±0.05mm

-

Permanent Magnet Synchronous Motors: Use rare-earth NdFeB magnets to reduce energy consumption by 45% vs conventional motors.

-

Smart Control Systems: 32-bit microprocessors enable millisecond response times with self-diagnostic capabilities.

-

-

200,000-Cycle Endurance Test: Simulates 10 years of intensive use with zero critical component failures.

-

125% Overload Test: Guarantees absolute safety under extreme conditions.

-

Expert Technician Team: Critical processes supervised by engineers with 15+ years of experience.

-

Dual Inspection System: Every elevator undergoes 36 factory tests + third-party certification.

Related news

"Residential Elevator Market Poised for Strong Growth Through 2032"

Global residential elevator market to reach $118.67B by 2032 (7.9% CAGR). Asia-Pacific leads with 51.2% share. Key drivers: urbanization, aging population, and premium living trends. Traction elevators with machine room dominate due to efficiency and smart features.

2025-11-12

FUJI round elevator:The Perfect Integration of Design Aesthetics and Smart Technology

FUJI round home elevator blends Eastern aesthetics with smart technology, featuring 360° panoramic design and customization. With patented hydraulic system saving 30% energy, it offers 5-year warranty for high-end residences.

2025-11-05

Elevator solutions